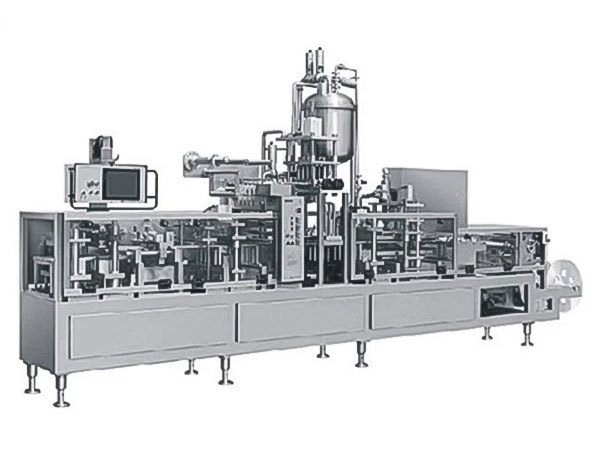

Plastic Cup Forming Filling Sealing Machine

Key words:

Plastic Cup Forming Filling Sealing Machine

Classification:

Key words:

Email:

- DESCRIPTION

-

- Commodity name: Plastic Cup Forming Filling Sealing Machine

Suitable for all kinds of yogurt, milk, beverages, butter, cheese, condiments, ice cream and other materials packaging, production from 3000 cups / hour to 6000 cups / hour, automatic molding plastic cup forming, filling, sealing, date printing, Die-cutting and product delivery. The main configuration of the device servo drive, programmable logic control, human-machine interface, temperature control, optoelectronics, pneumatic lubrication control systems are used internationally renowned brands. The series of equipment with cup, cup, butter, cheese and other functions of the models, is a modern enterprise high-quality high-performance, low-power fully automated production equipment.

Integrated punching die combination, the use of high-grade steel mold, long life. Mold based on the concept of rapid replacement of design, through simple adjustment, can be achieved two, four, six punch punching.

100-level clean air laminar flow system for forming filling grade clean air positive pressure protection, improve the finished product hygiene standards and shelf life. The machine movement parts servo motor drive, and the use of the latest motion control technology, work station synchronization, flexibility, more optimized machine running more stable, higher productivity. Equipment integrated CIP device to ensure contact with the material piping, valves, valves, pistons, etc. to achieve complete cleaning, in line with health standards.

Photoelectric detection servo drive correction system to ensure that the molding, punching station accuracy.

Unique external filling system, the application of the latest rotary valve and valve body, high filling accuracy and the filling process to minimize the shear force on the material, the material viscosity has been well protected .

Can be equipped with online fruit (jam), flavor dynamic mixing device to ensure that fruit and material mix, fruit breakage rate is low.Technical Parameters:

Filling capacity:

100ML-150ML

Maximum production capacity:

6000-12000cups

Filling error:

plus or minus 1%

Seal pass rate:

≥99.5

Total power:

20KW

Power:

50HZ380V / 220V (three-phase five-wire)

Air pressure:

≥0.6-0.7Mpa

Related Products

Leave us a message

Please leave us a message and we will contact you as soon as possible