Pasteurized milk production line

Key words:

Pasteurized milk production line

Classification:

Key words:

Email:

- DESCRIPTION

-

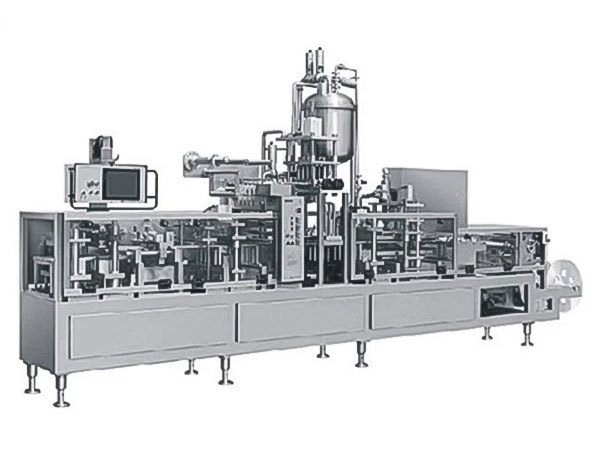

- Commodity name: Pasteurized milk production line

A pasteurized milk production line is a production line for various foods made from fresh cow (sheep) milk as the main raw material.

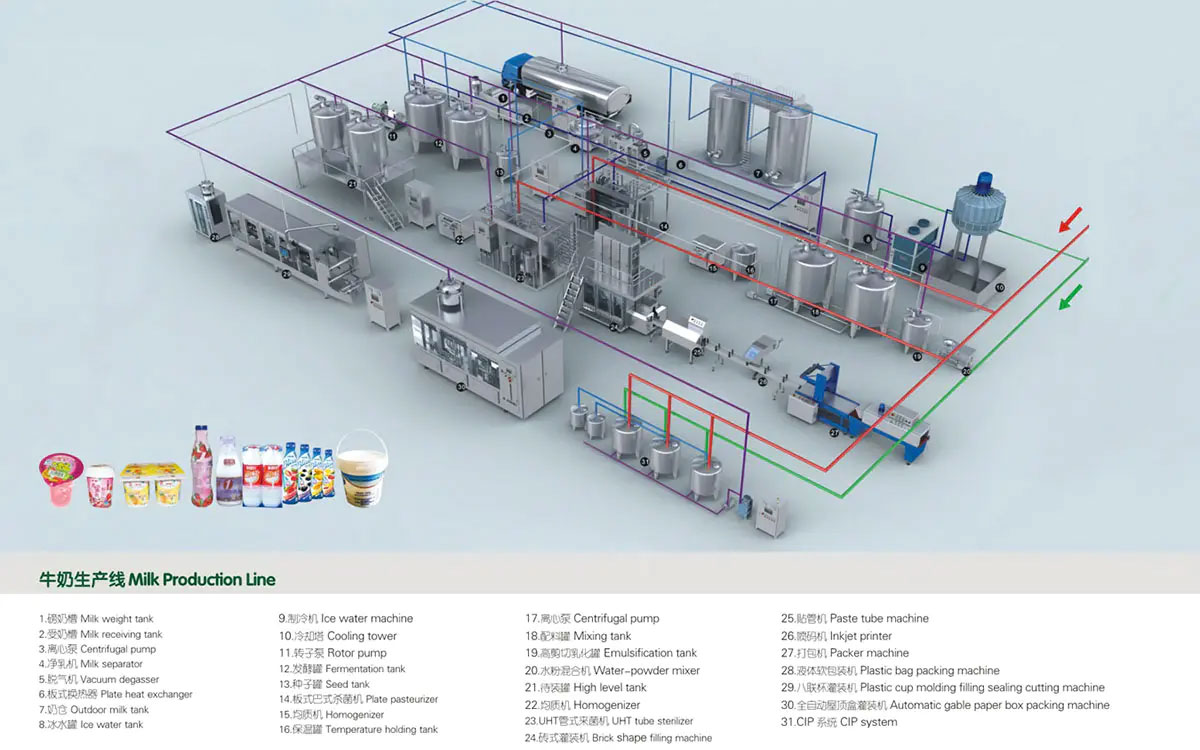

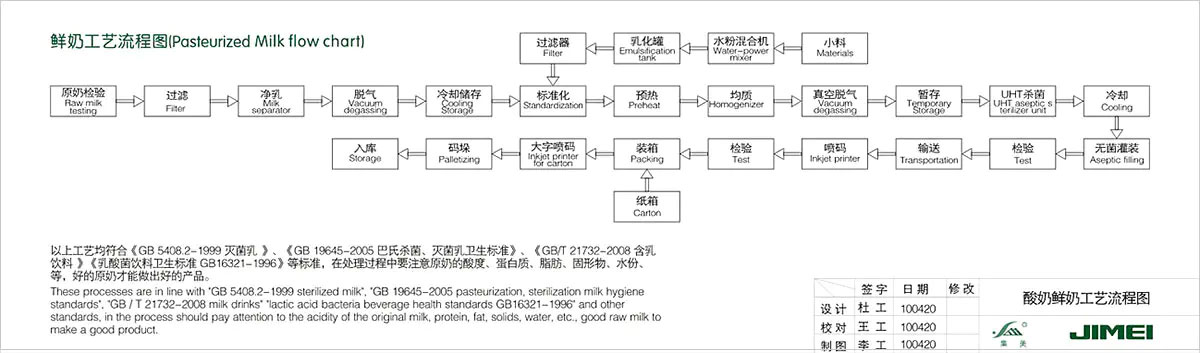

Pasteurized milk production line starts with Raw cow (sheep) milk as the main raw material, processed into various food production lines. Raw milk acceptance, after filtration, cream separation, pasteurization, degassing, storage, mixing, sterilization, and filling processes, warehousing for sale. Pasteurization kills pathogenic and spoilage bacteria in milk, ensuring product safety and maximizing the retention of fresh milk's nutritional components and unique natural taste. Nutritional value is not much different from fresh milk. Because pasteurized milk is not completely sterilized, bacteria remain in the milk, and these bacteria multiply rapidly at suitable temperatures, so refrigeration is necessary, generally with a shelf life of about 7 days.

Technical Features

Raw Materials: Fresh cow (sheep) milk

Finished Products: Various pasteurized milk products

Finished Product Packaging: Liquid soft packs, brick packs, gable top packs, plastic bottles, paper cups, plastic cups, glass bottles, etc.

Our company undertakes the design of milk production lines and factories with capacities from 2 to 1000 tons per day, as well as the installation, commissioning of factory equipment, and personnel training. We welcome customers to visit our company for discussions.Technical Parameters

Raw Materials Fresh milk, powdered milk Production UHT whole milk UHT skim milk UHT flavored milk Capacity 2T/D–500T/D End Product Packaging Brick-shaped aseptic cartons, pillow-shaped aseptic bags, plastic bottles, etc.

Related Products

Leave us a message

Please leave us a message and we will contact you as soon as possible